HOW WATER TANKS WORK

To start off, make sure your water tank is high quality. If you are collecting rainwater, you are not 100% sure the water collected is safe for consumption or usage; it might contain bacteria and possible diseases. You must obtain a high-quality water tank storage that has proper utilities that can sift and filter through the water to guarantee the water is safe to use.

A water storage tank with a filter keeps clean water from your reverse osmosis system until you need it in your home or business. A water source, such as a well or a recycled water system, is pumped into the tank. Reverse osmosis systems filter water gently, one drop at a time. A reverse osmosis storage tank means that you have access to clean and fresh water whenever you need it, rather than having to wait for the system to fill your glass each time. Many wells have poor pressure and recovery and are tasked with supplying pressured water to a home and/or business. When you turn on your shower, a well pressure tank guarantees that you have quick access to pressurized water. The water in the tank builds up until it’s full. Water is then transferred from the tank to your tap when you turn on your kitchen sink or your bathroom tap, providing you with fresh water on demand. The storage tank allows instant access to water when you need it, whether it’s to fill your glass with purified fresh water, take a shower, or water a whole field.

Water storage tanks come in an array of shapes, sizes, layouts, and are utilized in the water treatment industry for a variety of reasons. Thousands of gallons of rainwater can be stored in large, outdoor tanks. UV inhibitors are generally installed in these tanks to prevent algae and bacterial growth inside the water tank. Water heaters with the lid closed are also protected from leaking and bursting by thermal expansion tanks.

If you’re debating on water tank vs pressure tank, well a pressure or atmospheric tank are the most common types of water storage tanks. Pressure tanks are commonly used in point-of-use applications such as filtration storage tanks. Atmospheric tanks are commonly used in outdoor applications or large-scale public water storage operations.

WHERE ARE WATER TANKS GENERALLY USED?

You’re in luck if you are currently residing in places that have unlimited and free water available. You will surely have an adequate supply of water, with no hassle. Here are just a few ideas on where you can use your water tanks:

Agricultural use and farm water irrigation systems.

You don’t have to worry about watering your plants if you live in a frequently rainy environment. However, there will be months where drought is occurred, you’ll need a reliable source of water for your agricultural land. Watering your plants and crops with rainwater is much more environmentally friendly and safe. It’s more efficient and cost-effective than using the city’s water supply. Since plants and crops are a natural resource, it doesn’t need to be filtered thoroughly like the water us humans use for consumption. Rainwater for crops provides natural nutrients that are suitable for healthy and good plants.

Industrial usage or home water tanks.

Aside from drinking and keeping ourselves healthy and safe from bacteria, we need water to assist us in our daily lives. We can utilize the water gathered in the tanks to do things like washing our clothes, flushing the toilet, and washing our cars, and even cleaning our pets, among other things. Collecting water can help you save a lot of money on your water bill.

For drinking water.

As previously stated, water is essential for our survival. We drink it not just to be hydrated, but also to stay healthy. Bottled water is not always available to everyone. Plus, it’s not environmentally friendly to consume bottled water with plastic water bottles. After drinking from it, those bottles will be chucked into bins causing more garbage in our environment. If you don’t have access to a municipal water supply, you can drink the water collected inside the tanks but just make sure you filter them first, which is usually less expensive, more efficient, and less waste-producing than bottled water.

Use in a fire or an emergency.

Many places of Australia are classified as fire-prone, thus water should be easily available in the event of a disaster. However, water may not always be available due to fire damage in most accidents, where can we get water to put out the fire?

Firefighting water tanks designed specifically for these calamities have been mandated by the government and fire departments. Because the water will be used to put out the fire, it will not need to be tested for quality. The most crucial thing is that it should be easy to use. If you have water tanks, you can make it easier for firefighters to get them by posting a notice outside your home indicating that you have some water storage tank available.

HOW TO DECIDE WHICH WATER TANK IS THE BEST FOR YOU?

One of the most crucial things to figure out when choosing a proper sized water tank is if it meets you and your demands. “Which water tank is the best?” is an important question to ask yourself. You don’t want a water tank that’s so small that it overflows in the rain and runs dry in the heat. You also don’t want a water tank that is so large that it costs extra and takes up too much space.

Also, one of the main considerations you need is what water tank size do you need. You have two aspects that must be assessed: the quantity you receive from your source and the amount you consume. You’ll be able to decide on the water tank’s size you need.

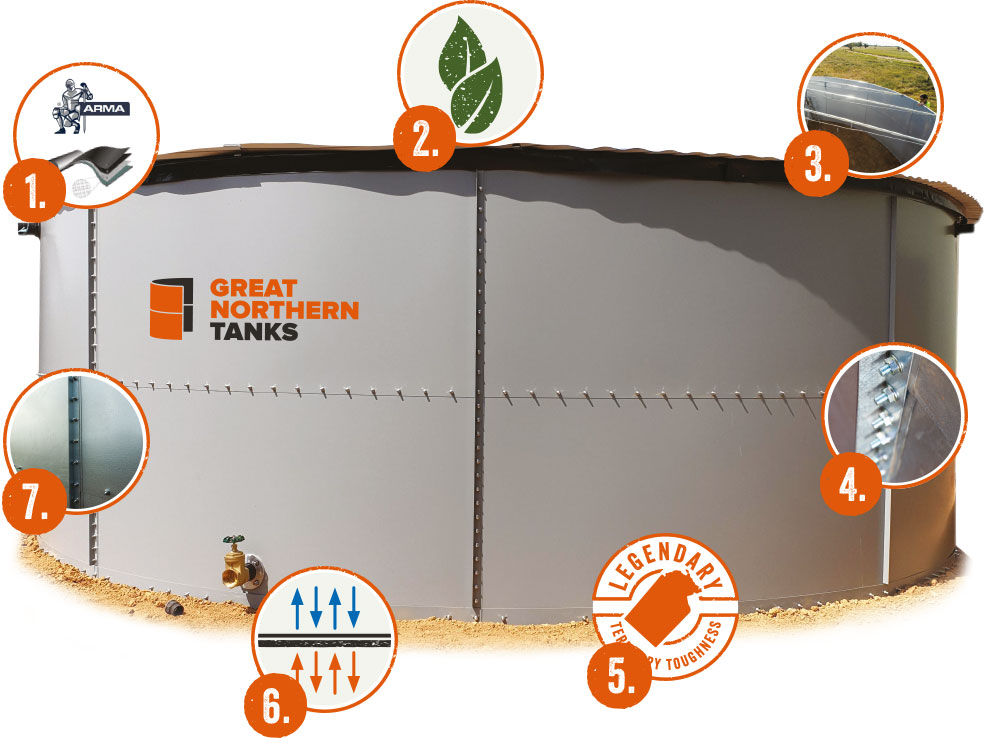

Great Northern Tanks can provide and guide you on which water tank you’ll need. You can see what materials you’ll need; what the water tanks are made up of, the best area where you’ll want your water tank to be built on, how water tank cleaning works, which water tank colour is best for your location, why water tank cleaning is important, how water tank works in general, and even the size of the tank are all linked and important when it comes to understanding, choosing and making use of them. It’s now just a matter of assessing the advantages and drawbacks of each form of water tank to get the most out of them.

WHY WATER TANK FILTRATION IS IMPORTANT?

Water is, without a question, the most important aspect of our lives, and we cannot live without water. It is important for cooking, personal hygiene, and areas where cleaning is concerned, in addition to quenching our thirst. As a result, it’s critical to keep your water tanks clean by employing professionals to do it.

While the facts show that water recharges us, excretes pollutants from the body, helps us in different ways but it can also cause a variety of illnesses when consumed in its impure or sullied form. That is why it is critical that the water we drink or use to cook with is fully clean, pure and filtered. To do so, we must clean and purify the water tanks that have been installed in our areas, agricultural land and workplaces on a regular and daily basis. The following are a few benefits of water tank cleaning to consider:

Frameworks for water filtering are not perfect.

While statistics show that many of us have water filtration systems installed in our homes and workplaces, they may not be fully effective if the water inside the water tanks isn’t clean and purified. Water tanks may contain specific types of particles and bacteria, therefore, water filters may not be fully effective in preventing contamination and, as a result, specific types of water-related illnesses may be consumed. Regardless of whether the water tank is underground, above, RCC or plastic, it is important to hire experienced water tank cleaning services.

Many hazardous microorganisms can be found in clean water.

If you don’t clean your water tank on a regular basis, it can lead to the deposition of contaminants in the water, which can include a variety of deadly microorganisms. That being the case, water could be contaminated with a variety of bacteria that causes disease, including loose bowels, cholera, gastroenteritis, and a few others. Dirty water tanks can also be contaminated over time and become hazardous to use, even for cleaning.

The leading cause of illnesses worldwide is contaminated water.

It is well known that contaminated water is the sixth leading cause of diseases and deaths worldwide, trailing only cigarette smoking on the list. The bulk of us don’t bother cleaning our water tanks on a regular basis, but this laid-back attitude could lead to fatal diseases. Whether you use filtered or unfiltered water for drinking and cooking, there are several areas where unfiltered water is utilised, such as washing utensils, brushing our teeth, and so on, and as a result, we consume it in some ways or another. You will need to hire a professional to clean your water tank.

WHAT ARE WATER TANKS USED FOR IN RURAL AUSTRALIA?

Many rural properties in Australia do not have access to public water supplies and must rely on private wells. Rainwater, hauled water, ground water, and surface water are some of the additional alternatives. Farm water tank prices for the installation and the tanks itself depends on the location, size and dimension you need. Carted water is the most expensive of them, as it can be inconvenient, costly, and inefficient. Water quality, licensing, and availability difficulties can affect groundwater and surface water supplies, making them only acceptable for stock or irrigation in some cases. Rainwater is the finest alternative for home use, especially if you have a large catchment area or farmland and adequate guttering on your house and any surrounding sheds.